System Overview & Benefits

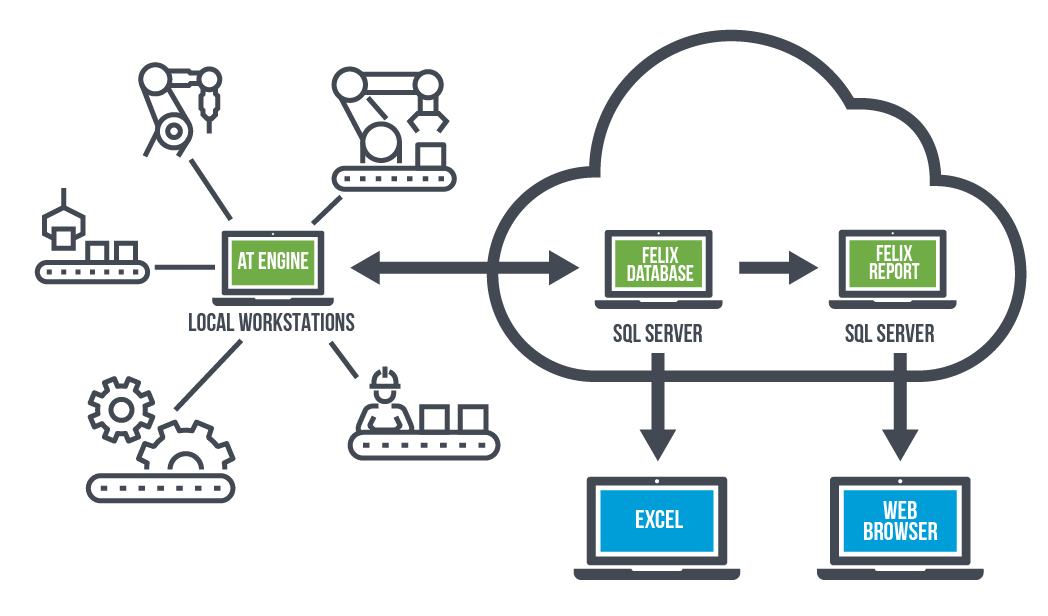

Cloud based

- Hosted on secure and reliable Azure Service cloud servers. Customers always have access to the latest server hardware and don’t need to upgrade their own IT infrastructure

- Real-time back up and redundancy due to server structure. System restore possible in the event of complete hardware failure

- Can be deployed globally and quickly into a single or multiple customer locations

- Customer can deploy in key supplier locations to monitor quality and output of key processes creating a ‘virtual’ factory

- remote access to all functionality

- Can be managed and configured from a central location

- Can easily be scaled to meet changing business requirements

- In most cases uses existing customer infrastructure with little additional CAPEX required

System capability and reliability

- Core platform has been in continuous use for over 10 years

- Demonstrated reliability and robustness

- >99.9% uptime limited by Azure Server guarantee

- For large manufacturing company running 24/7 operating on FelixCloud platform ( •15M serial number records held •4M serial numbers allocated annually •103K sequences run daily •2M daily operations processed )

- Fast* store and retrieval of data means no lag in system performance (* speeds subject to quality and reliability of internet connection and internal network capacity)

- Ongoing improvements mean that basic feature set continues to be improved so investment in solution is future proofed

Process control

- Manage fully or semi automated manufacturing process. High levels of customization possible.

- Extensive library of equipment that can be controlled by AT Engine

- Deliver Manufacturing Instructions electronically according to the task being performed

- Ensure required equipment including tools, jigs and fixtures are in calibration and being used correctly based on site definition & configuration

- Control limits can be set and triggers activated if activity detected outside these limits

- Control and monitor forward as well as rework process

- Deliver Manufacturing Instructions electronically according to the task being performed

- Support RMA management and recovery

- Collect/capture inspection pass fail criteria and store results including weight, dimension and pictures

- If required program information collected during manufacturing process into product

Improve productivity

- Monitor equipment utilization and asset tracking including tools, jigs and fixtures

- Provide information to support cost control and productivity* and monitor improvements (* when implemented and used correctly typically deployment will pay for itself within 12 months through improved efficiency, less scrap and less re-work)

- Multi language support

- Support operational planning

- Common data available for use in decision making by all business functions via standard or custom dashboards and reporting tools

- Supports multiple test environments** so product qualification testing can be implemented efficiently (** for example -40°C, +25°C & +90°C)

Traceability

- Detailed real-time reporting information of all activity being managed by FelixCloud

- Perpetual data storage of all recorded events give full traceability including material*, build configuration, operator, pass/fail, Site ID, number of times event has been run, shift, location (*component serial number, lot, batch)

- Allows rapid implementation of corrective and containment activity

- Allows side by side comparisons of different simulations to be run with high confidence in the same production environment. This is key to supporting continuous improvement objectives.

- All changes to process are recorded and can be linked to the product produced

Employee management & engagement

- Monitor employee performance compared to peers and motivate employees to demonstrate consistency and improvement

- Maintain training records

- Define roles and responsibilities in system to control actions based on role and skill

- Each employee has a unique ID which can be used for attendance monitoring

- Data from system can be used for calculation of incentive bonus and other benefits

Reporting tools

- Historical and real-time data available

- Ability to drill down multiple levels to see linked detail from high level summary

- Built in analysis tools for quick data review

- Standard and custom reports are available to allow detailed analysis by operator, shift, process*, time of day, material batch, product family, etc (* FTPY, throughput yield and FTPY based on dependent process for both normal and rework process flows)

- Onboard data analysis tools allows graphing of results by time and value as well as calculation of Cpk, mean, SD, max and min test values

- Real-time display of WIP including normal material and rework/scrap material

- Generate plots and other technical data for engineering reports

Additional capabilities

- Import and export data from other business tools such as ERP or PLM systems. This can be done in real time or by batch file data exchange

- Manual or automated data entry

- Use information to generate and print packing slips and invoices for shipments including customer purchase order numbers and quantity

- If required automatically upload test results to customer specified location in required format and interval

- Issue RMA numbers and collect repair information on debugged product